Transformers are vital devices that play a fundamental role in the efficient transmission and distribution of electrical power. Their primary job is to step up or step down voltage levels, allowing electricity to travel efficiently over long distances.

This pivotal function ensures that the electrical power generated at distant sources can be distributed to homes, schools, and industries without significant losses. However, transformers face challenges like moisture infiltration, corrosion, insulation impurities, and even physical winding movements that can put them at risk of imminent failure.

In this article, we’ll break down these issues and provide simple solutions to extend the lifespan of transformers, thereby working to prevent expensive repairs, premature replacements, and ensuring the reliability, safety, and uninterrupted operation of electrical power systems.

1. Moisture Infiltration

Moisture poses a significant threat to the life of transformers as it has the potential to infiltrate the insulation system over time. As moisture accumulates within the transformer insulation, it leads to the degradation of dielectric strength.

Dielectric strength is the ability of the insulation to withstand voltage without breaking down. When moisture weakens the insulation, the transformer becomes more susceptible to electrical faults, which can ultimately result in catastrophic failure.

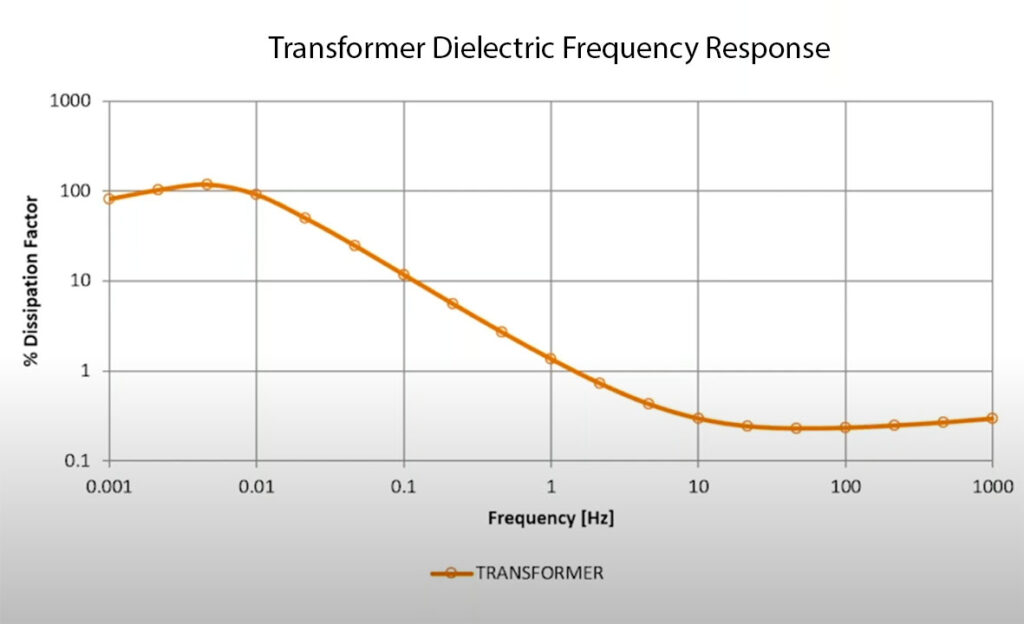

When moisture is present in the insulation, it can lead to changes in the capacitive and resistive properties of the insulation system. These changes can be detected by analyzing the response of the insulation using Dielectric Frequency Response (DFR) Analysis.

During the DFR test, the insulation response is measured at different frequencies, typically ranging from a few Hz to several kHz. The measurements are then compared to reference measurements or established standards to evaluate the insulation condition. The test results can provide information about the presence and severity of moisture within the insulation system.

Once moisture has been detected, it must be removed. One of the most advanced and efficient methods of drying transformer windings is the low frequency heating method. During this heating process, the water from the paper insulation is transferred into the oil, and the oil is then removed using a thermal vacuum dryer, eliminating the need to remove the windings from the transformer.

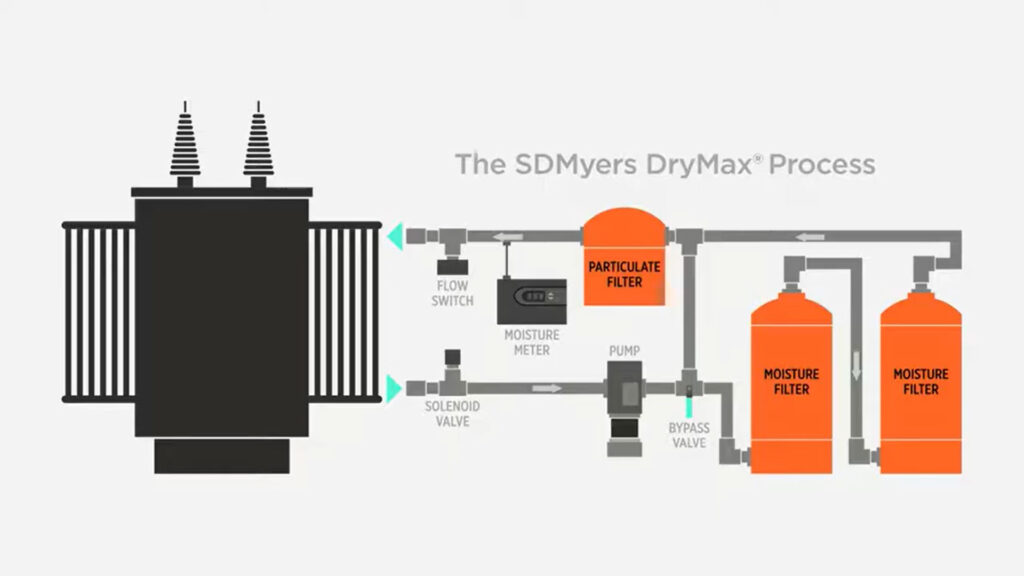

Transformer oil dry out systems utilize water absorptive media to remove moisture from transformer oil. These are ideal for applications where vacuum cannot be used and/or just moisture and particulate removal is required.

2. Oxygen and Corrosion

Oxygen, an important element in the atmosphere for humans, can exert a detrimental influence on transformers. It facilitates the aging of insulation materials and encourages corrosion of metal components inside the transformer.

The interaction of oxygen and heat with the insulating oil in the transformer leads to the formation of acids in the oil. The aging accelerators of acid and oxygen work together to promote breakdown of the oil-cellulose system.

High oxygen consumption speeds up the aging process and the aging process produces acid, which increases oxygen consumption. Corrosion weakens the structural integrity of the transformer and can lead to mechanical failures or physical shifts in transformer windings.

To detect the acid and oxygen content in transformer insulation, you can take periodic oil samples or use an on-line gas monitor for around the clock analysis. Acid Number and Interfacial Tension are useful indicators of oil quality when considered together along with the transformer design.

Although oil regeneration can remove oxygen from the system, many of the acids remain in the paper insulation and continue to degrade the cellulose, contributing to accelerated oxidation. Preventing oxygen ingress and ensuring adequate cooling is the best defense against acid formation.

3. Solid Impurities

Solid impurities, such as dust, dirt, and other contaminants, may find their way into a transformer. These impurities accumulate over time and can have dire consequences. They interfere with the normal operation of the transformer, causing partial discharges, increased heat generation, and a reduction in overall efficiency. Additionally, the presence of solid impurities makes the breakdown of insulation worse, accelerating the transformer’s aging process.

Transformer oil filtration is a process of removing impurities and contaminants from the transformer oil to ensure its quality and performance. The oil is circulated through a filtration system that typically includes pumps, filters, and sometimes additional equipment like heaters or vacuum chambers. The impurities such as solid particles, water, gases, and degraded oil are removed through various filtration methods, such as mechanical filtration, vacuum dehydration, and degassing.

4. Varnish Deterioration

Varnishes are frequently used in dry-type transformers as insulation materials to protect the windings and other internal components. However, these varnishes are not immune to the harsh operating conditions to which transformers are exposed.

Over time, the combination of heat and electrical stress can cause varnishes to deteriorate. When varnishes break down, they compromise the insulation’s integrity, leaving the transformer susceptible to electrical faults and eventual failure.

Varnish deterioration often manifests as a dark or sticky residue on the insulation surface. During visual inspections, look for any signs of discoloration, cracking, or peeling. Use a thermal imaging camera to detect any hotspots on the transformer. Varnish deterioration can cause localized overheating, which will appear as abnormal temperature variations.

Dielectric testing, such as Polarization Index (PI), is a method used to detect varnish deterioration from transformer insulation. A higher leakage current across the insulation with a low PI can indicate that the varnish coating on the insulation has degraded. An Insulation Resistance Profile (IRP) can be obtained by plotting the measurements over a discreet increment for graphical analysis.

5. Winding Movement

The physical structure of a transformer is not immune to factors that can affect its life. One such factor is the slackness or movement of windings within the transformer.

Mechanical shifts can induce stress on the insulation materials, causing them to weaken and degrade. As the insulation deteriorates, the risk of electrical faults increases, ultimately jeopardizing the transformer’s functionality.

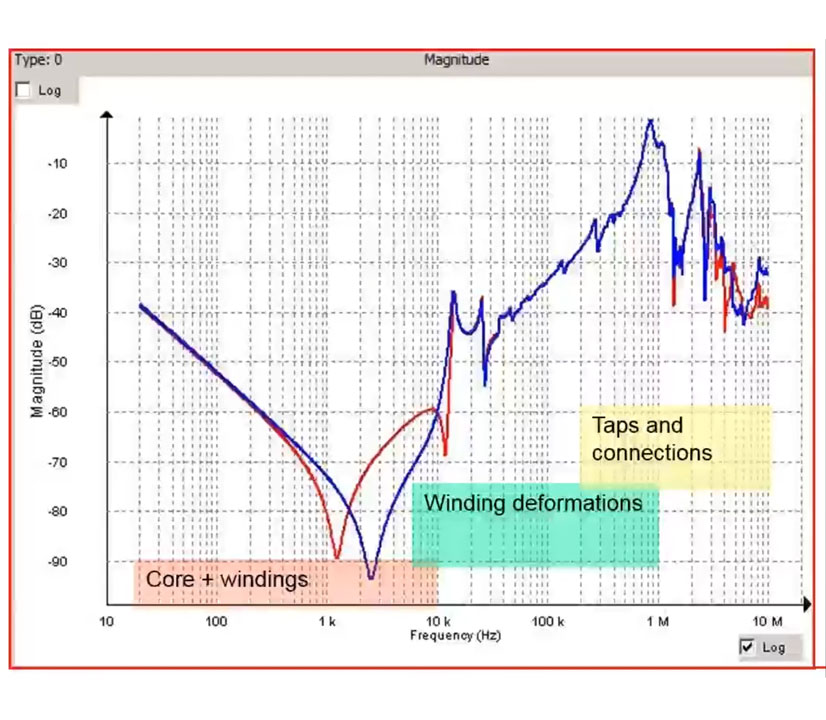

Sweep Frequency Response Analysis (SFRA) helps identify winding movement in transformers by sending electrical signals through the windings at different frequencies and analyzing the response. Any significant deviations in the response compared to a reference measurement of a healthy transformer can indicate the presence of a winding shift.

Conclusion

Transformers are indispensable components of our electrical infrastructure, ensuring the smooth flow of electricity across power systems. However, their reliable operation hinges on their ability to withstand various environmental and operational challenges.

Moisture, oxygen, solid impurities, varnishes, and winding movement are all factors that can significantly impact the life of transformers. To ensure their longevity, regular maintenance and monitoring are essential.

By mitigating these factors and promptly addressing any issues that arise, asset managers can extend the life of transformers, ensuring a stable and efficient power supply for years to come.