An electrical substation is a critical component that transmits electric power from production to consumption. Within a substation, various equipment—such as switchgear, transformers, power system protection, communication devices, voltage regulators, and energy meters—work together to ensure the safe and efficient delivery of power.

Substations vary in size and function. For instance, a small substation might supply power to a few homes, while a larger one could provide electricity to an entire car manufacturing plant or a small town.

To guarantee the safe and reliable operation of a substation, many devices and systems, including protection relays and circuit breakers, are necessary. However, implementing these safety systems can involve numerous devices from different manufacturers, making the protection system complex and challenging to maintain.

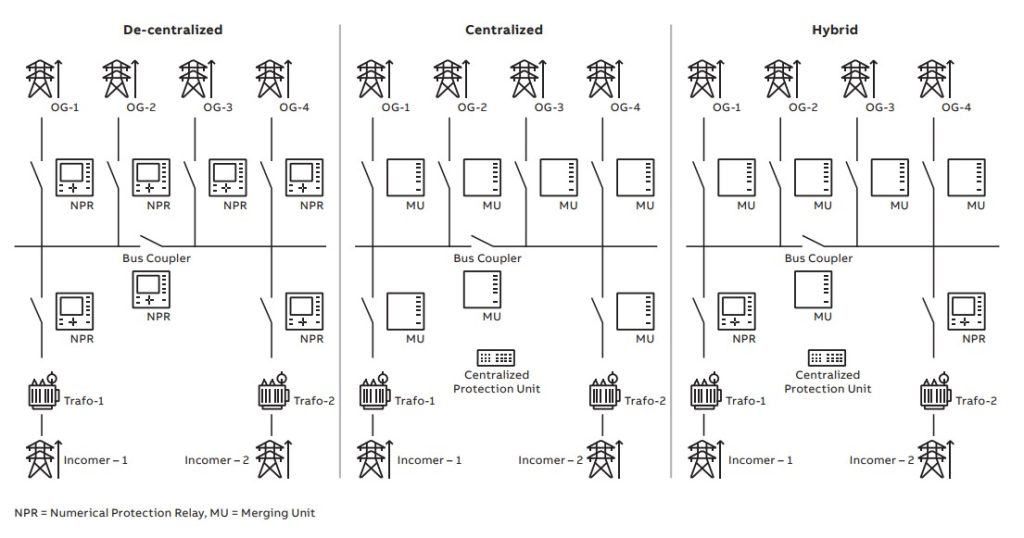

Conventional “De-Centralized” Protection Systems

In a conventional substation protection and control scheme, protection is distributed or “de-centralized” among multiple Numerical Protection Relays. These devices typically operate independently, with minimal communication and coordination between them. Each relay is responsible for a specific protective function, such as overcurrent, differential, or distance protection, and they function autonomously within their designated roles.

This decentralized system has been the standard for many years. However, with advancements in microprocessor technology, modern relays can now integrate multiple protective functions into a single unit. Despite this integration, each substation cubicle still performs all of its own processing and logical functions independently. This means that while one relay might manage several protective tasks, it still operates in isolation from other relays within the substation.

The primary challenge with this approach is the complexity it introduces. Having numerous independent devices increases the difficulty of ensuring coordinated protection and control, which can lead to inefficiencies and potential reliability issues. Additionally, the maintenance of such a system can be labor-intensive, as each device requires individual attention and expertise.

Modern “Centralized” Protection and Control Systems

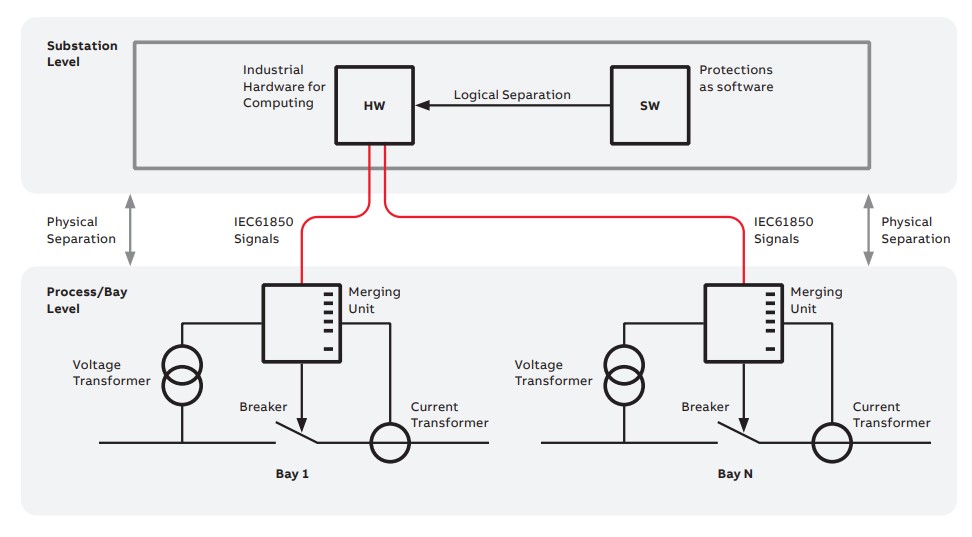

Centralized protection and control (P&C) is a modern approach where all P&C functionality is centralized into a single device at the substation level. With this method, it is possible to protect and control a wide variety of utility and industrial applications from a central device.

The availability of a Centralized Protection and Control (CPC) unit allows for the concentration of all substation data—real-time data from the protection and control scheme, various primary equipment statuses, and measurements from protection current transformers (CTs) or sensors—at a single user interface point within the substation.

Key Advantages of Centralized Protection and Control

Centralizing all substation data at one location offers several significant benefits. This setup improves the user experience by providing centralized alarms, events, and disturbance recordings for all bays. It also enhances the efficiency and safety of controlling and operating primary equipment, facilitates centralized engineering, and simplifies the management of protection settings and configuration storage for substation devices.

- Centralized protection and control functionality within one device

- Enhanced ability to view and monitor processes at the substation level

- Flexible integration of a wide range of protection and control functions

- Capability to protect and control diverse utility and industrial applications

- Simplified testing and commissioning by injecting current and voltage signals to each merging unit (MU)

- Reduced engineering effort from start to finish

- Quick and straightforward system-wide upgrades

- Comprehensive disturbance recordings for the entire substation

- Optimal flexibility throughout the substation’s lifespan

CPC Technology Overview

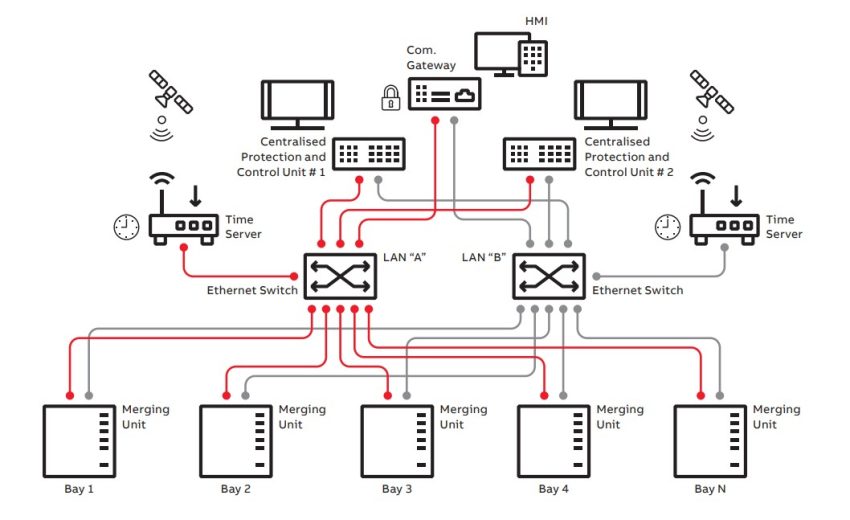

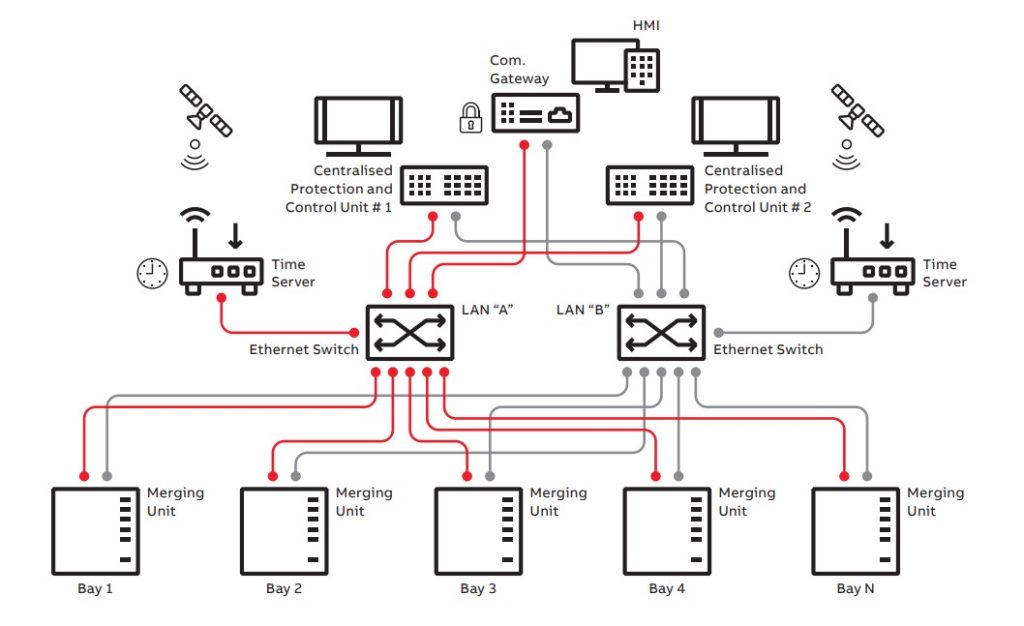

Centralized protection and control units can be deployed in several different architectures, depending on the other solution components used and overall system requirements. Typically, a CPC system will consist of the following:

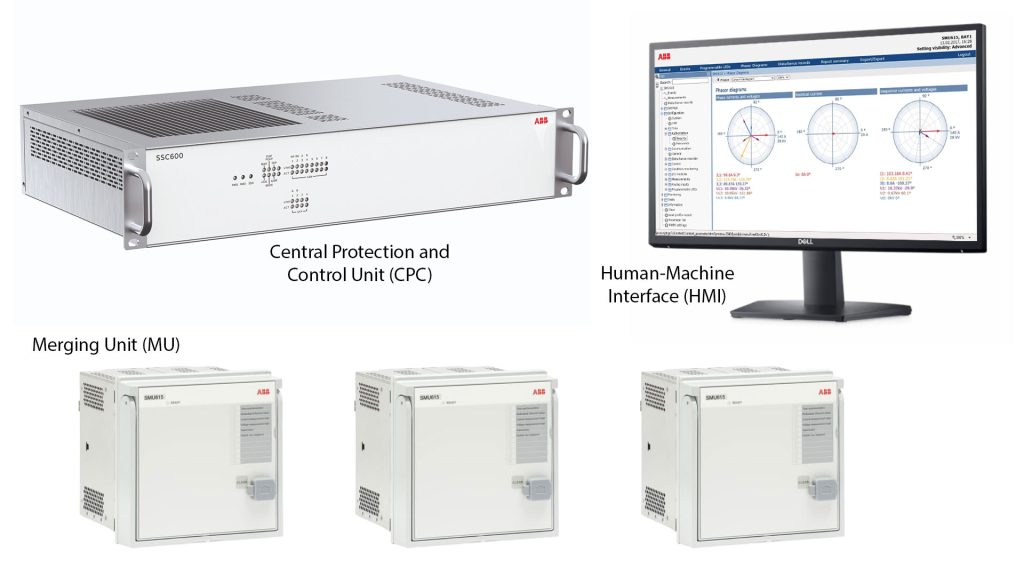

1. Central Protection Control Unit

The CPC unit can offer a web-based dedicated user interface, providing multiple HMI options throughout the substation over a secured LAN or even remote access through a secured VPN and internet. This may be a proprietary hardware device or standalone software that can be used in a virtualized environment with off-the-shelf computer hardware.

The central protection unit continuously monitors the entire system for:

- Phase currents

- Symmetrical components of the currents

- Residual current and residual voltage, based on the received process bus measurements

- Residual voltage

- Phase voltages

- Voltage sequence components

- Frequency

Additionally, the device offers three-phase power and energy measurement, including power factor. Disturbance recording, event logs, and condition monitoring of circuit breakers are also possible. The measured values can be accessed remotely via the communication interface of the device. The values can also be accessed locally or remotely using the Web HMI.

2. Merging Unit

The Merging Unit (MU) acts as a link between instrument transformers—both conventional and non-conventional—and the relay or CPC unit. This unit accepts inputs from current transformers (CT), voltage transformers (VT), and binary inputs (BI). It then generates multiple time-synchronized digital outputs for data communication across logical interfaces. By converting analog signals from instrument transformers into digital formats, the MU facilitates centralized protection functions.

The merging unit serves as a vital physical interface connecting primary equipment within switchgear to protective devices in the power system. It accurately measures current and voltage signals from instrument transformers, merges them, and transmits standardized digital outputs to protective devices.

Additionally, the MU supports input/output modules to manage digital signals from feeders. It communicates the operational status of primary equipment—such as circuit breakers, isolators, and earthing switches—to network devices, while also receiving signals for trip, open, or close actions from external units.

3. Network Switches

Network switches play a pivotal role in enabling seamless digital communication across various components within the substation infrastructure. These switches facilitate reliable and high-speed data transmission between merging units, the centralized protection unit, HMIs, and other essential network components.

In a substation environment, network switches ensure that data from merging units, which convert analog signals from instrument transformers into digital formats, can be efficiently transmitted to the centralized protection unit. Likewise, they enable the bidirectional flow of information, allowing the protection unit to issue commands and receive status updates from HMIs and other network devices.

Network switches form the backbone of the substation’s communication infrastructure, enhancing interoperability and enabling advanced functionalities that are crucial for maintaining optimal performance and safety in power distribution systems.

4. Substation Time Synchronization

Substation time synchronization leverages Ethernet-based technology to achieve precise software-based synchronization with an exceptional accuracy of 1 millisecond.

The ability to synchronize time with 1 millisecond accuracy ensures that events and actions within the substation are precisely timestamped, facilitating effective fault detection, sequence-of-events recording, and coordination of protection schemes. This level of synchronization also supports seamless integration with broader utility networks and compliance with regulatory requirements for grid stability and reliability.

Risk Mitigation

In architectures employing a CPC system, ensuring high availability and reliability of the communication network is essential. For effective risk mitigation, redundancy options must be carefully considered.

A primary approach to redundancy involves duplicating the central device. This redundancy strategy guarantees that in the event of a device failure, full protection functionality remains operational.

By maintaining identical configurations between redundant central protection devices, engineering and maintenance tasks remain efficient. During update procedures and testing phases, the redundant unit can seamlessly assume protection duties while the other unit undergoes maintenance or upgrades.

Hybrid Systems

Another approach to redundancy involves combining simplified conventional relay protection with centralized protection and control (CPC). In these hybrid systems, intelligent merging units play an important role by providing backup protective functions. These merging units essentially act as microprocessor relays capable of communicating with the centralized protection unit.

Cyber Security

The threat of cyber attacks is a serious concern for all computerized and networked systems, including key equipment in centralized systems such as relays, merging units, and CPC units.

To mitigate these risks, increased awareness and advancements in cyber security are essential to safeguard electric grids. Implementing measures such as authentication and authorization protocols, audits with comprehensive logging, and rigorous product and system hardening are essential.

Firewalls, intrusion detection or prevention systems (IDS/IPS), and VPN technology play pivotal roles in protecting the CPC system’s key equipment. Additionally, verified malware prevention software helps secure central computers by detecting and defending against cyber attacks and viruses. These proactive measures are integral to maintaining the integrity and reliability of CPC systems in the face of evolving cyber threats.

Event Logging

An audit trail serves as a chronological record of system activities, enabling the reconstruction and examination of system and security-related events and changes. Both CPC units and merging units are equipped with extensive event-logging capabilities. Critical security-related events from these units are logged into a dedicated nonvolatile audit trail accessible to system administrators.

Conclusion

Centralized Protection and Control (CPC) systems represent a significant advancement in the management and safeguarding of electrical substations. By consolidating protection and control functionalities into centralized units, these systems enhance operational efficiency, improve system reliability, and streamline maintenance efforts.

The integration of intelligent merging units and robust network infrastructure enables seamless communication and data synchronization, supporting real-time monitoring and rapid response capabilities. The adoption of CPC systems introduces enhanced cybersecurity measures, including authentication protocols, auditability, and system hardening, to mitigate risks posed by cyber threats.

As the utility and industrial sectors continue to evolve, CPC systems stand poised to meet the growing demands for smarter, more resilient power infrastructures. With their ability to optimize resource utilization, enhance grid resilience, and ensure uninterrupted power supply, CPC systems represent a cornerstone in modernizing and securing electrical substations for the future.

References

- Centralized Protection and Control – ABB

- Dell Validated Design for Energy Edge

- Centralized Protection & Control – PAC World