Electrical power systems testing is a three part algorithm that consists of isolation, application, and evaluation. Traditionally this process has been carried out between asset owners and service companies, with expensive contract agreements that span over a decade or more.

Finding a service provider you can trust is the first challenge and then contracting often requires extensive time to negotiate. Once the agreement is finalized, the process of assembling labor and hauling in test equipment begins.

The current process of electrical testing

After safely isolating an apparatus, test technicians will begin the painstaking process of hooking up leads and applying some form of voltage or current to a component. Test values are recorded, results are analyzed, and a condition assessment of that apparatus is made. If all goes well, the process is reversed and power is restored.

It goes without saying this entire operation requires a large amount of time, energy, and resources. It is also very expensive and a hazard to human life, which is why many asset owners will spend money on risk managers to evaluate how much they can save by extending maintenance or putting it off all together.

Automation in electrical testing is already here

At one time, electrical testing was an art form, but with the technological advancements that have been made over the past 20 years in relation to information technology, it wont be too long before much of the manual process is reduced, if not eliminated entirely.

Modern test equipment is already starting to move towards automation as each manufacturer tries to gain an edge on the competition by making operation of their equipment easier on the user. Relatively very little knowledge is now needed to perform electrical tests when compared to how things were done twenty years ago.

Project managers are always looking to save time and test equipment designs are getting to the point where you only need to know how to safely isolate a piece of equipment and where to hook up the leads. Many test plans are built directly into the test equipment, and all that is required can be a push of a button. Results can then be imported to reporting software or downloaded to memory with very little user intervention.

Combination test equipment is becoming more prevalent as manufactures try and integrate different types of testers into a single package. As this trend continues, all that will be left in the process of electrical testing is knowing how to properly evaluate test results and restore the equipment to service without blowing it up.

What if electrical apparatus was able to test itself?

When it comes to routine maintenance, service technicians are mostly only needed for operating the equipment and making evaluations based on their results. The process itself is subjective because inconsistent test procedures will often lead to erroneous results.

Much of this inaccuracy and manual labor could be eliminated if electrical apparatus was designed with test equipment already built in. Automated systems require very little human intervention and oversight compared to the amount of labor required when doing it manually.

Introducing Self-Testing Apparatus Terminal

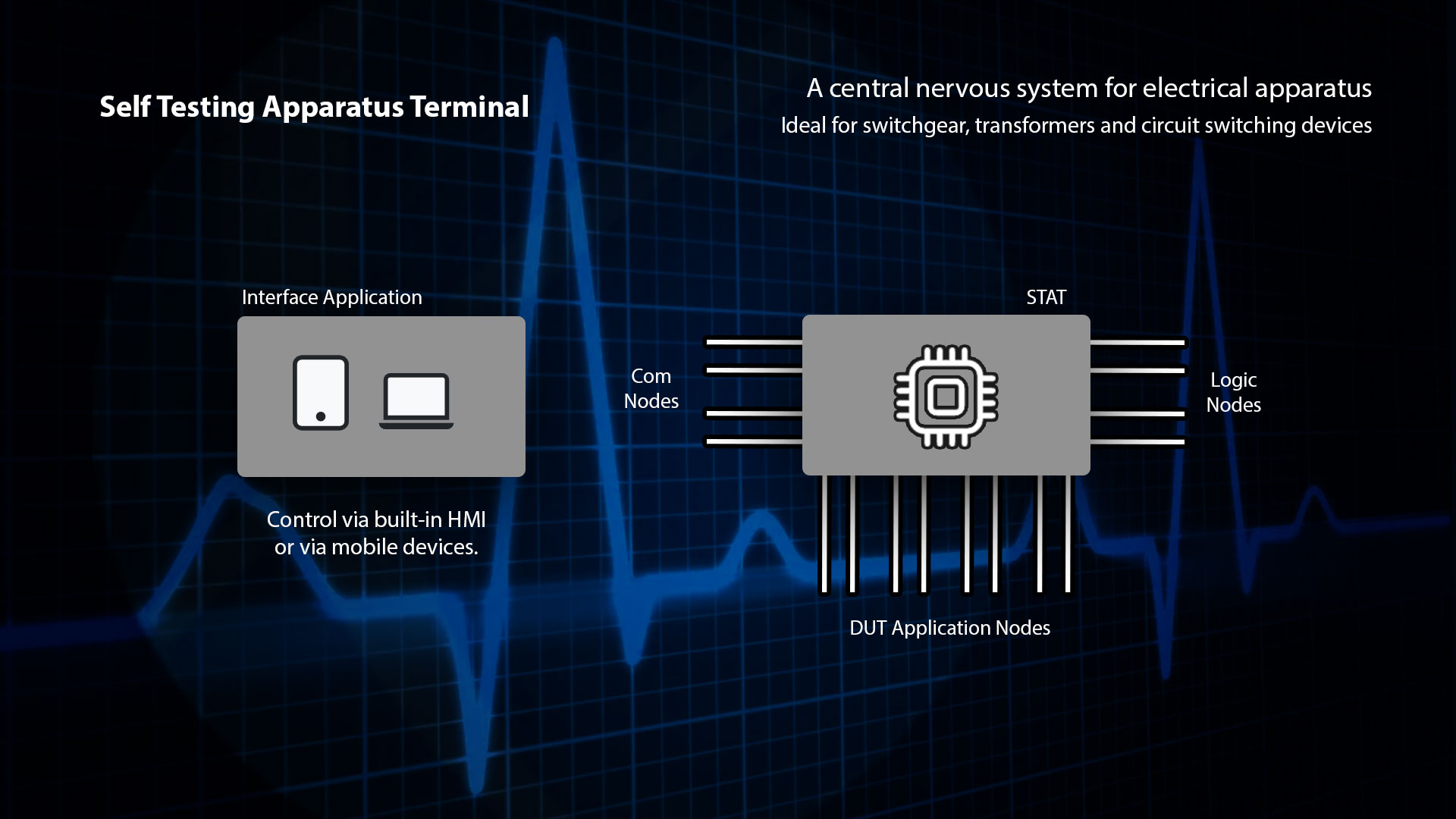

Araium has been developing a central nervous system for electrical apparatus that will disrupt the testing process. We call it the Self Testing Apparatus Terminal (STAT), a fully-automated routine testing solution that is ideal for switchgear, transformers and circuit switching devices.

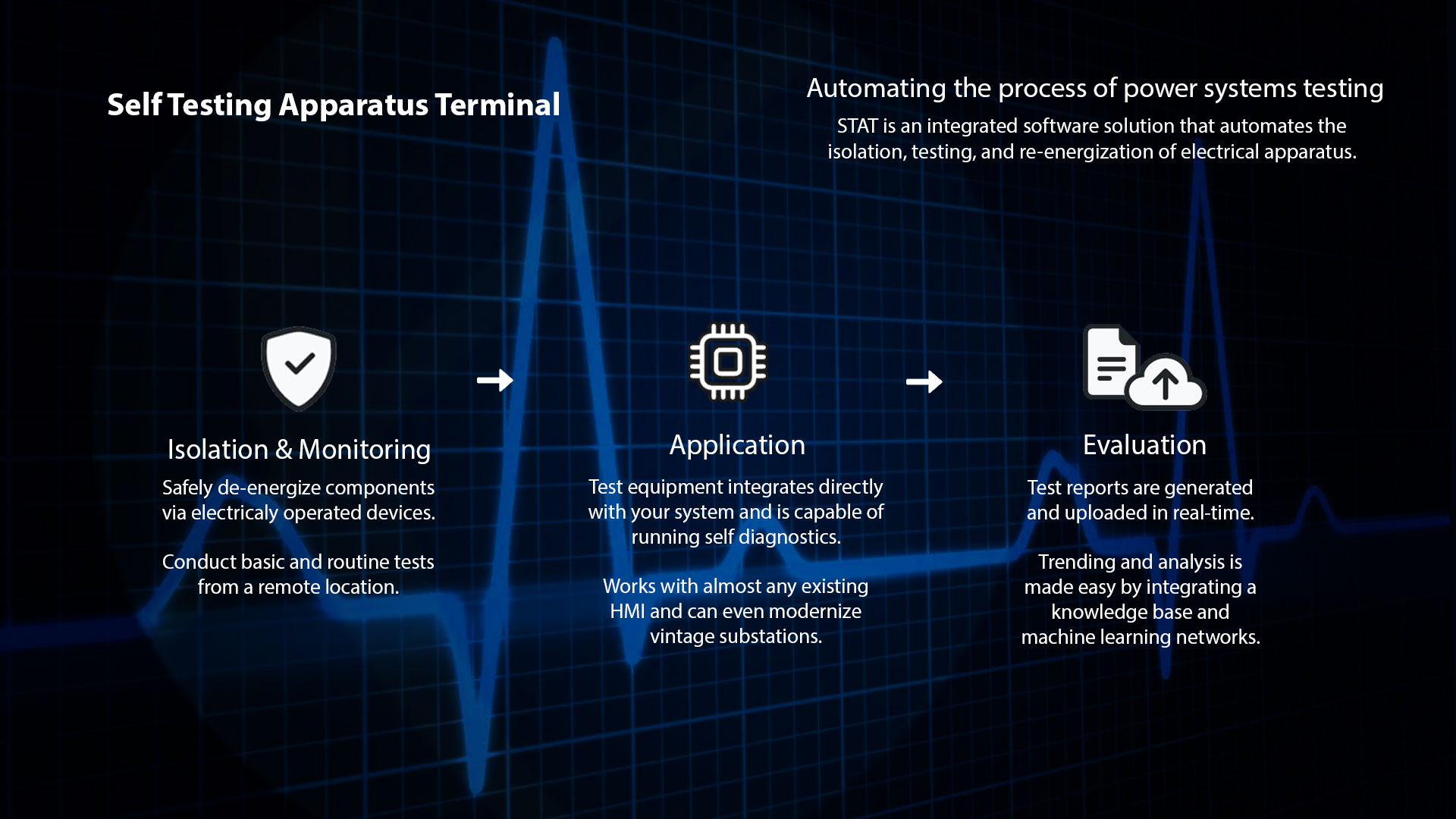

Forget about contracting expensive testing companies for simple, run-of-the-mill tests. STAT is an integrated software solution that automates the isolation, testing, and re-energization of electrical apparatus.

Real-Time Monitoring and Self Diagnostics

STAT integrates test equipment directly with your system and is capable of running self diagnostic tests.

- Connection Resistance

- Insulation Resistance

- Secondary-Injection

- Ground Fault Checks

- Electrical Operations

- Environmental Monitoring

- Partial Discharge

- Arc Flash Mitigation

Advancing the Smart Grid with Direct Data Upload

No more waiting for the testing company to produce your reports. Test results are generated and uploaded instantly to our fully managed database or your own custom solution. Trending and analysis is made easy by integrating a knowledge base and machine learning networks.

Easy integration with almost any SCADA system

STAT can work with almost any existing HMI and can even modernize vintage substations.

Cost Savings Potential

The longer you own an asset, the lower the cost of ownership becomes, assuming maintenance costs are kept to a minimum. By eliminating the need for expensive oversight, you can run more frequent maintenance intervals, further increasing the value of your investment. This is the power of automation.

Ready to experience the future?

Autonomous systems are here and will soon be impossible to avoid. We can already fly planes and drive cars with little human intervention, so why should electrical testing be any different? Contact our technology consultants to discuss your current needs and see if a self-automated testing solution is right for you.