In the realm of power systems maintenance, two prominent standards reign supreme: NFPA 70B Standard for Electrical Maintenance and NETA Maintenance Testing Specifications. While they share a common goal of ensuring electrical reliability and safety, a closer examination reveals significant differences in their approach, scope, and focus.

In this article, we will delve into the key disparities between NFPA 70B and NETA MTS, shedding light on their unique requirements, methodologies, and applications within the electrical power industry. By understanding these distinctions, industry professionals can navigate these standards effectively and make informed decisions to optimize maintenance practices and enhance electrical system performance.

NFPA and NETA: What’s the difference?

Before we dive into the details of each maintenance standard, let’s first take a look at the history and structure of both organizations.

Mission and History

The National Fire Protection Association (NFPA) is a global self-funded nonprofit organization devoted to eliminating death, injury, property and economic loss due to fire, electrical and related hazards.

The mission of the International Electrical Testing Association (NETA) is to lead the electrical power acceptance testing, commissioning, and maintenance testing industry through: education; standards development; accreditation of independent, third-party testing organizations; and certification of test technicians.

While both organizations are involved in electrical safety, NFPA has a broader focus on fire protection and covers a wider range of hazards. On the other hand, NETA specializes in electrical power systems testing and aims to be an industry leader in that specific area.

The NFPA was established in 1896 and has a long history of over a century. NETA was founded in 1972, making it a relatively newer organization compared to NFPA.

Membership Base

NFPA has a large membership base of individuals worldwide. As of 2023, the NFPA claims to have 50,000 members and 9,000 volunteers working with the organization through its 250 technical committees.

NETA is guided by an active Board of Directors consisting of professionals within the electrical testing industry. These members hold quarterly meetings and also participate on various NETA committees, such as the Standards Review Council, Certification Exam, Membership, Finance, Association Development and Strategy, Promotions and Marketing, Nominations and Mission Based Programs.

It is unclear exactly how many members NETA has, but it accredits a large number of third-party electrical testing firms and certifies electrical testing technicians within those firms. Along with its corporate alliance program, NETA has a very wide reach in the electrical maintenance industry across North America.

Authors

Both NFPA and NETA documents are authored through a consensus standards development process approved by the American National Standards Institute. This process brings together volunteers representing varied viewpoints and interests to achieve consensus on best practices and safety issues.

NETA firmly endorses a global standardization, which is why they changed from the “National” to the “International” Electrical Testing Association. This means IEC standards as well as American consensus standards are taken into consideration by NETA’s ballot pools and reviewing committees.

Standards Development

NFPA develops and publishes more than 300 consensus codes and standards related to fire protection, electrical safety, and other areas. NETA produces standards related to electrical power systems testing, commissioning, and technician certification only.

In addition to codes and standards, NFPA delivers information and knowledge through research, training, education, outreach, advocacy, and partnerships with other organizations. NETA accredits third-party electrical testing firms, certifies electrical testing technicians, hosts an annual conference, and publishes a quarterly technical journal. Both organizations share a focus on education, standards development, and training/certification.

Simply put: NFPA aims to address fire, electrical, and related hazards in various industries and sectors, while NETA specifically aims to be the worldwide expert in electrical power systems and equipment assessment.

Examining the Fundamental Differences in Electrical Maintenance Standards

The purpose of NFPA 70B is to provide for the practical safeguarding of persons, property, and processes from the risks associated with failure, breakdown, or malfunction and a means to establish a condition of maintenance of electrical equipment and systems for safety and reliability.

The purpose of NETA MTS is to assure tested electrical equipment and systems are operational, are within applicable standards and manufacturer’s tolerances, and are suitable for continued service.

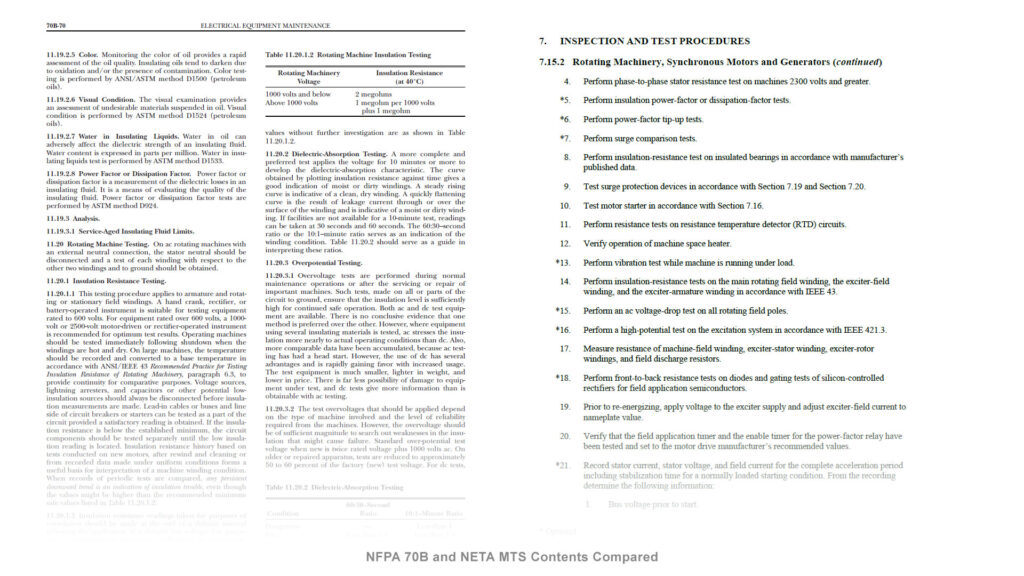

NETA specifications provide the procedures related to electrical maintenance, including the sequence of testing and inspections, along with expected test results and recommended values. NFPA 70B has a similar structure, with a focus on detailed explanations, and actionable terms that make the outcomes mandatory and enforceable.

NFPA standards discuss the basic theory behind various tests, including an entire chapter on the fundamentals of electrical equipment maintenance. In total, 70B contains over 30 chapters on equipment ranging from the basics like transformers, circuit breakers, and rotating machines to more advanced situations like Electrical Disaster Recovery and Vibration Analysis.

NETA specifications cover a broad range of high-, medium-, and low-voltage equipment but are much more basic in their structure, with each section broken down by visual/mechanical inspections, electrical tests, and expected values. There is very little informational content, just mainly tables and references.

Who is responsible for enforcement?

NETA specifications are voluntary standards developed by the International Electrical Testing Association. Unlike regulations, which are enforced by government authorities, compliance with NETA standards is typically not mandated by law. However, adherence to NETA specifications is widely recognized and considered best practice within the electrical power systems testing industry.

NFPA standards are widely recognized and influential in the field of fire protection and safety but their adoption and enforcement can vary by jurisdiction. Different regions may adopt specific editions of NFPA codes or modify them to suit local requirements. The specific enforcement authorities and processes may differ from one jurisdiction to another.

While the NFPA itself doesn’t have any type of regulatory authority, their standards have been adopted by many governmental agencies. In the United States, for example, OSHA has incorporated NFPA best practices into their standards.

NFPA standards may also be enforced by Fire Departments, Building Inspectors, and Insurance Companies. Perhaps the most well known standard by NFPA is the National Electrical Code, which is commonly enforced by many government and regulatory agencies across the United States.

With the release of the 2023 edition, NFPA 70B became a standard by introducing mandatory language for the maintenance of electrical equipment. Prior versions were labeled as a “recommended practice” for electrical maintenance.

Navigating Between NETA MTS and NFPA 70B for Effective Maintenance Strategies

Both NFPA 70B and NETA MTS offer valuable guidance for creating an electrical maintenance plan. Each document is structured differently and have several key distinctions in the information they provide.

- NFPA 70B contains a large amount of explanatory material regarding the inspections and tests involved, with detailed information and insight to the purpose of each test. NETA MTS, on the other hand, is styled like a check list of tests to perform, along with recommended test values based on other industry specifications and manufacturer values.

- NFPA 70B can be used in conjunction with other NFPA standards, such as NFPA 70 (National Electrical Code) and NFPA 70E (Electrical Safety in the Workplace), to ensure a comprehensive approach to electrical safety and maintenance.

- NETA MTS is designed to complement other industry standards and specifications, including those published by organizations like NFPA and IEEE (Institute of Electrical and Electronics Engineers).

Key Considerations for Effective Electrical Maintenance

NFPA 70B now as a standard in 2023, sets the tone for which electrical maintenance is mandatory and enforceable, while NETA MTS is best used as supplemental material for the recommended test values and expected results for each test.

Whether leveraging the preventive maintenance emphasis of NFPA 70B or the comprehensive testing procedures outlined by NETA specifications, adopting best practices from both standards can lead to improved reliability, safety, and longevity of electrical power systems.

References

- NFPA 70B-2023: Standard for Electrical Equipment Maintenance

- NETA MTS-2023: Standard for Maintenance Testing Specifications for Electrical Power Equipment and Systems

- New For 2023: NFPA 70B